Manufacturing Execution Systems

Manufacturer, finish, ship and communicate with unmatched tracking and reporting capabilities. MillTools may be the only MES with ROI.

Manufacturer, finish, ship and communicate with unmatched tracking and reporting capabilities. MillTools may be the only MES with ROI.

TestCentral combines QCS data and lab tests to ensure only good products ship to customers. Track reels and rolls. Chart and export priceless data.

Increase quality of product grades, reduce costs and solve problems. PantherQCS is scalable advanced process control all pulp and paper mills.

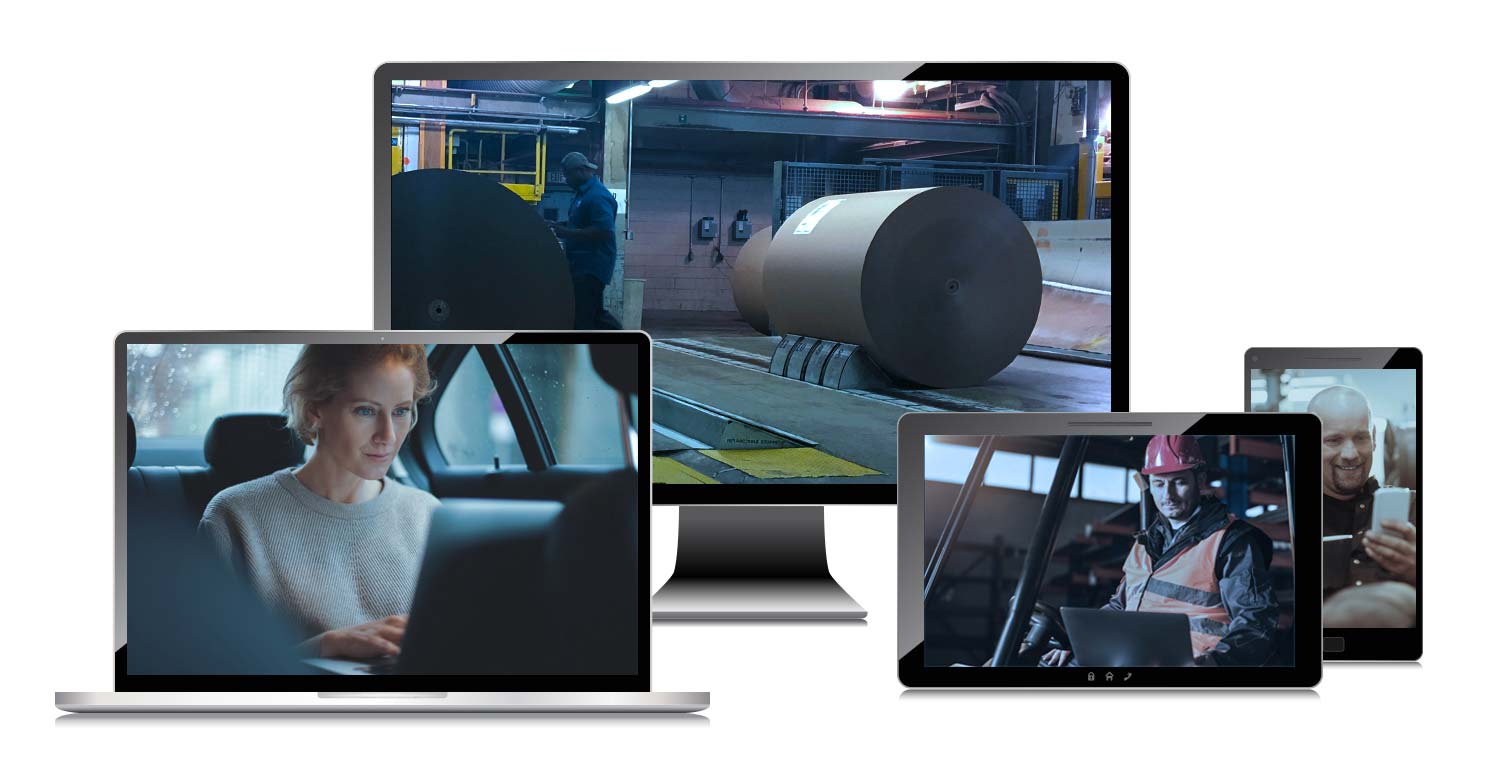

Use off-the-shelf workstations and connected devices with Chromium browsers

View, report, export and send data to anyone who needs quality and manufacturing intelligence

Modern and intuitive user experiences that speak the language of any country and company

Monitor quality and production remotely and securely from anywhere

Tools for everyone from the shop floors and loading docks to the corporate headquarters

MillTools leverages your own configuration, group privileges and customer profiles, so your MES matches mill process and business rules on computers and mobile smart devices. And these details are key to helping your people to be productive and make intelligent decisions. So, you just found the most customer-configurable MES for pulp, paper and nonwoven manufacturers.

PantherQCS is a game-changer for mills and plants striving to improve product quality, reduce waste and avoid unscheduled downs. So, reset the end-of-life clock on legacy scanners and sensors. Improve paper machine control. eliminate sheet breaks and conserve fiber. Enhance performance, lower maintenance costs and see a noticeable ROI. We can show you how.